Model-Based Definition – First Step Towards Model-Based Enterprise

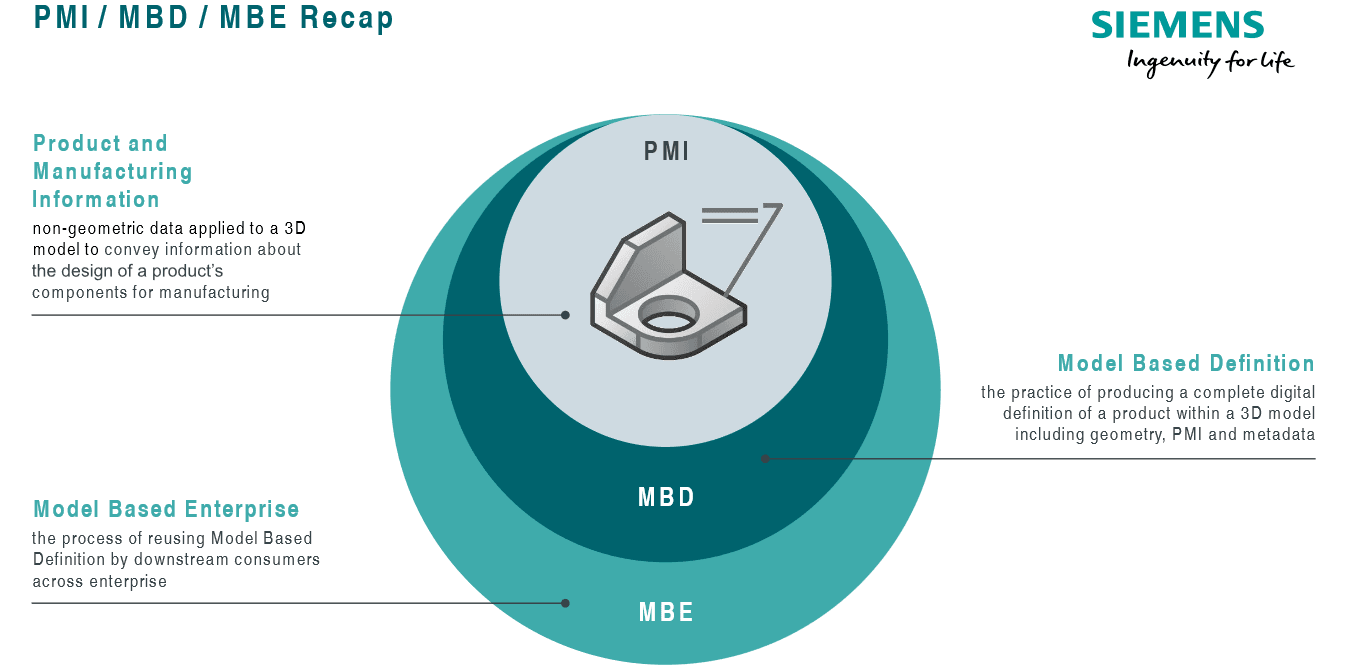

We recently published a blog on Model-Based Engineering and Model-Based Systems Engineering. This blog continues on the same theme, focusing on Model-Based Definition (MBD). To get started, the most important terms are explained in the figure below.

In general, industrial companies are under constant pressure to reduce costs, improve quality, and release new products quicker. These topics are going to be even more important when the world starts to recover from COVID-19 pandemic. The reduced cost, better quality, and shorter R&D lead times can be achieved by improving data flow in product development, product engineering, and manufacturing processes. Did you know that it is possible to improve data flow by taking PMI, MBD, and MBE into use? Return on investment (ROI) for MBD has been studied more in detail for example by Lifecycle Insights [2].

What is model-based Definition?

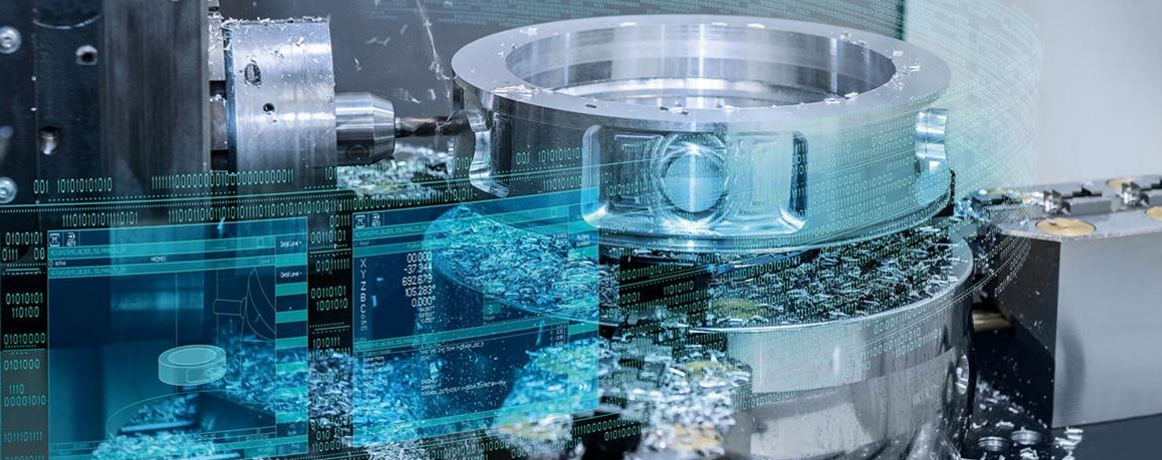

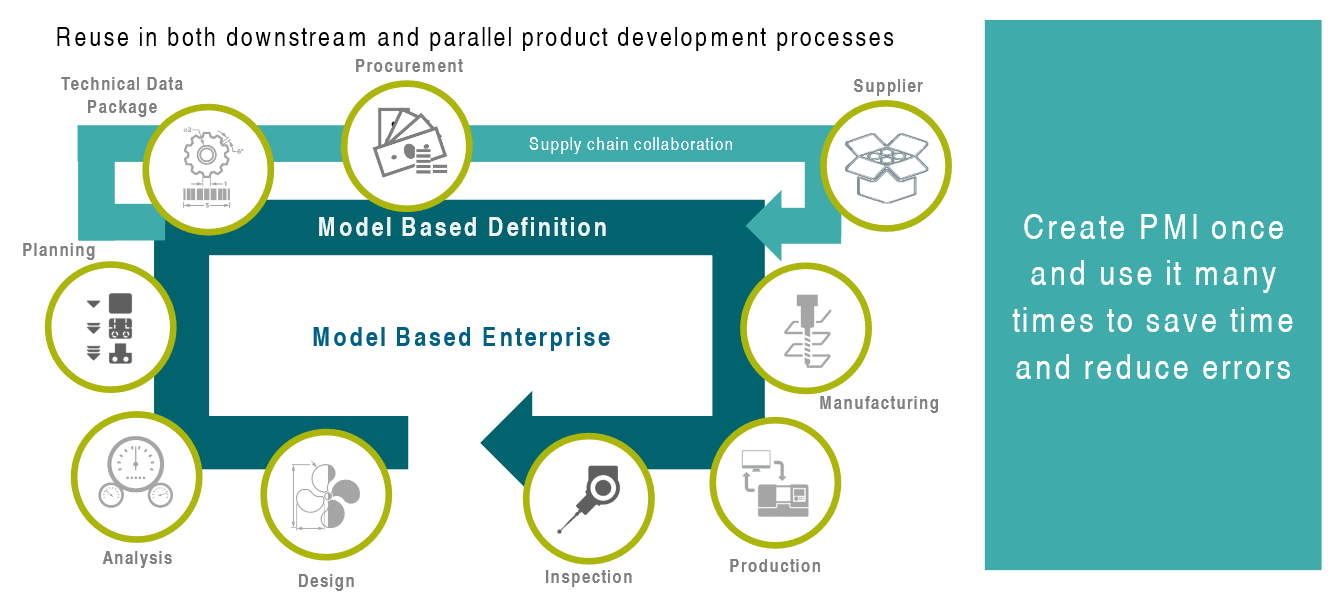

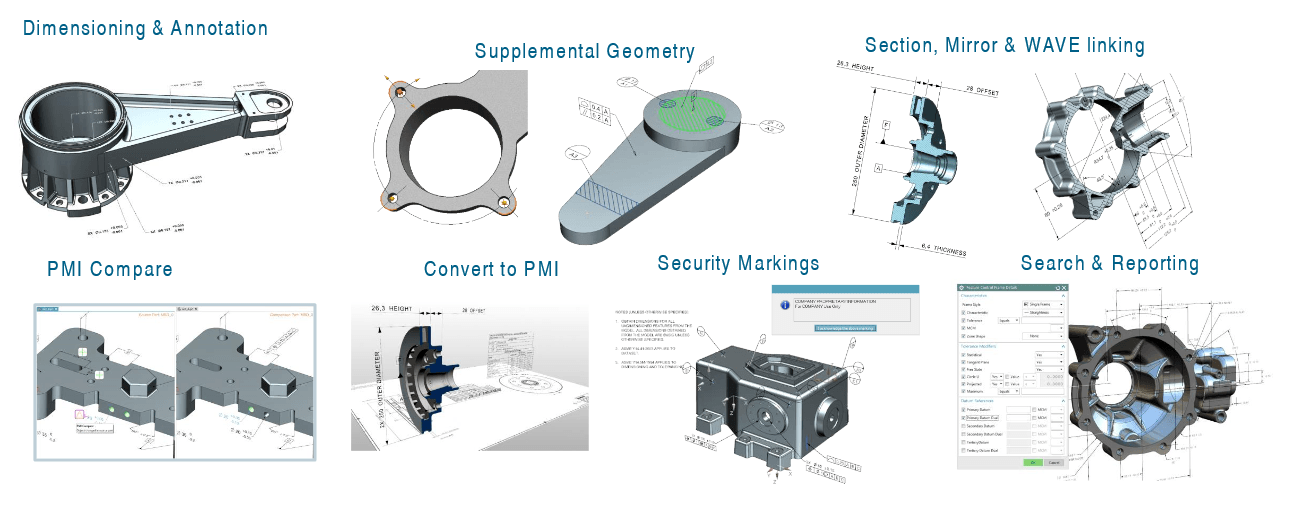

MBD is not actually a new term or technology. Siemens has released first functionalities in the early ’90s. However, during the past years, PMI, MBD, and MBE have become more and more common topics of “coffee table discussions”. Discussions are usually focused on adding annotations to 3D models in CAD software. However, there are so many other aspects that should be discussed. What if annotations are not read by the human eye at all? PMI information can be created only once in engineering and reused for example in analysis, machining, and inspection processes [3]. The biggest benefits of PMI/MBD/MBE can be gained if the information is shared and consumed efficiently in downstream processes with minimal human interaction. Possible reuse cases are illustrated below.

Efficient data consumption requires data to be in the correct format for the downstream processes. Whether the data is consumed by a human or machine, suitable format(s) can be found for all business needs. In addition to geometry, many of the formats allow you to also transfer annotations. In addition to native CAD-formats like NX-format, the data can be communicated downstream by using formats like JT, STEP, and 3D PDF. However, it is worth remembering that it is useless to add all drawing annotations to a 3D model. Only the really needed annotations like specifically tolerated dimensions and geometric tolerances should be added. Avoid creating a mess by fully annotating a model.

Instead of adding a large number of annotations, it is very important to consider how to utilize PMI efficiently e.g. in part manufacturing [4].

ASM has been able to reduce NC programming time 91% by combining PMI and feature-based machining, resulting in 70% part quality improvement and 70% production improvement.

Siemens: ASM Pacific Technology case study

As already mentioned, MBD has been there for a while and Siemens already has proven software tools, so it is up to you to make things happen. Now is the right time to get started with MBD which is the first step towards a completely Model-Based Enterprise.

References:

- Siemens Digital Industries Software (DISW), Internal documents

- Lifecycle Insights, The ROI of MBD

- Siemens DISW, Keys to a Successful Model-Based Definition Strategy

- Siemens DISW, Feature-Based Machining in NX CAM

More posts

Metso aiming to improve supply chain collaboration through system simulation

Webinar (THIS WEBINAR WILL BE HELD IN FINNISH LANGUAGE) (Material will be distributed in English) August 22, 2023 – 09:00 CET Learn how Metso utilizes system simulation in their hydraulic system design. Research engineer Jesse Backman shares his learning path to system simulation, and how Metso could improve the collaboration of the supply chain through […]

Metso pyrkii kehittämään toimittajayhteistyötä systeemisimuloinnin avulla

Webinaari 22.8.2023 – 10:00 EET Tule kuulemaan kuinka Metso hyödyntää systeemisimulointia hydraulijärjestelmien suunnittelussa. Tutkimusinsinööri Jesse Backman kertoo oppipolkunsa systeemisimuloinnin pariin ja kuinka Metso voisi kehittää yhteistyötä toimittajaketjussaan systeemisimuloinin avulla. Tärkeimmät opit esitellään käytännön suunnitteluesimerkin avulla. Kuinka parantaa yhteistyötä toimitusketjussa systeemisimuloinnin avulla? Mitä systeemisimulointi on? Systeemisimulointi yhdistää yksittäisten komponenttien ominaisuudet ja vuorovaikutukset koko järjestelmän dynaamiseksi käyttäytymiseksi. […]

From Chaos to Clarity: Embracing Modularity

by Olli Uuttu • 8 min read Dear reader, have you ever wondered what goes into building a truly modular product? It’s not as easy as it may seem. While there are several proven methods available to plan and implement optimal modular architectures, it still takes effort, dedication, and discipline to succeed. I’m sure you […]