Metso aiming to improve supply chain collaboration through system simulation

Webinar

(THIS WEBINAR WILL BE HELD IN FINNISH LANGUAGE)

(Material will be distributed in English)

August 22, 2023 – 09:00 CET

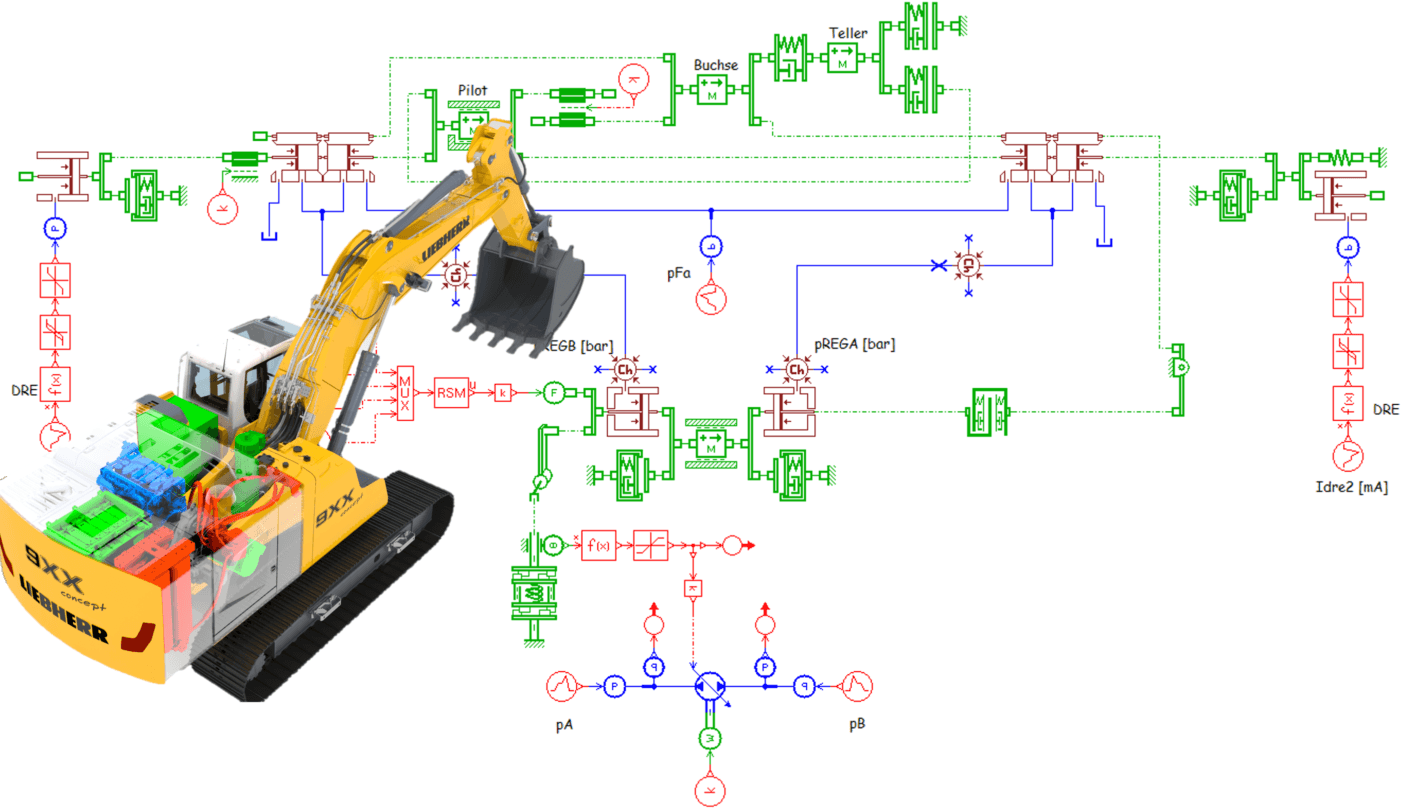

Learn how Metso utilizes system simulation in their hydraulic system design. Research engineer Jesse Backman shares his learning path to system simulation, and how Metso could improve the collaboration of the supply chain through system simulation models. Key learnings will be shared from a practical design case example.

How to improve supply chain collaboration through system simulation?

What is system simulation?

System simulation combines properties of individual components and their interaction into dynamic behavior of the whole system. Component design and selections can be confirmed by inspecting the correct system level operation with a virtual model.

Different physical domains can be considered in the same model, which enables comprehensive system design. Combining thermal, hydraulic, pneumatic and mechanical behavior with control logic, shows what really limits the system performance.

System simulation helps us understand what we really want from the component

Jesse Backman, Research Engineer, Metso

Key gains from system simulation – Why do I need it?

- Design effectivity increases with system behavior-based and optimized component sizing

- More evaluated concepts and innovations with easy and quick comparison of different technology and component variants

- Less sourcing and testing delays by understanding early on which component variants provide the desired system performance

- Improved testing quality by finding the relevant component variants and physical phenomenon to focus on

- Component quality defect identification through design parameter and tolerance sensitivity studies

How to get started?

Selecting the correct tool for your needs is the key. By testing the simulation tool with experienced support, you quickly gain the understanding of how to build a model with right level of detail. Connectivity between application software is an important feature that eases collaboration inside and outside your organization. Eviden will help you through your learning path to system simulation expertise.

“But we only design components!”

Components are always part of a system. Understanding the behavior of the system requires the knowledge of the component behavior. On system level models the component behavior can be described even with simple measured characteristic curves as long as the component behavior tests are done with this use case in mind.

What is important?

To keep up with the modern development pace it is crucial to have a tool in which the simulation model building and result analyzes is easy and quick. Flexibility to model different physical domains acting together, and possibility to start off with rough details gives the possibility to quickly evaluate different concept ideas and technology options. When component model definitions can be refined inside the used software the same base model can be utilized throughout the whole product development life cycle.

Is my core competence safe?

In system level simulations it is not necessary to have all the design details exposed.

Usually, the behavior of the component with respect to inputs is the key and therefore the business sensitive parameters can be left out of shared content. These so-called “black box” models still behave like the real components without revealing the magic that makes them tick.

More posts

Metso pyrkii kehittämään toimittajayhteistyötä systeemisimuloinnin avulla

Webinaari 22.8.2023 – 10:00 EET Tule kuulemaan kuinka Metso hyödyntää systeemisimulointia hydraulijärjestelmien suunnittelussa. Tutkimusinsinööri Jesse Backman kertoo oppipolkunsa systeemisimuloinnin pariin ja kuinka Metso voisi kehittää yhteistyötä toimittajaketjussaan systeemisimuloinin avulla. Tärkeimmät opit esitellään käytännön suunnitteluesimerkin avulla. Kuinka parantaa yhteistyötä toimitusketjussa systeemisimuloinnin avulla? Mitä systeemisimulointi on? Systeemisimulointi yhdistää yksittäisten komponenttien ominaisuudet ja vuorovaikutukset koko järjestelmän dynaamiseksi käyttäytymiseksi. […]

From Chaos to Clarity: Embracing Modularity

by Olli Uuttu • 8 min read Dear reader, have you ever wondered what goes into building a truly modular product? It’s not as easy as it may seem. While there are several proven methods available to plan and implement optimal modular architectures, it still takes effort, dedication, and discipline to succeed. I’m sure you […]

Recognizing the true potential in energy saving

by Kalle Ahola & Hannu Mäkinen • 6 min read Energy prices have recently been very unstable for all energy types. On both personal and commercial level this has increased the focus on energy usage probably more than in decades. Newspapers are filled with energy saving tips and tricks and most likely all of us have at […]