What’s new in Siemens Solid Edge 2023

In October 2022, Siemens Digital Industries Software presented the latest version of their product development software, Solid Edge 2023.

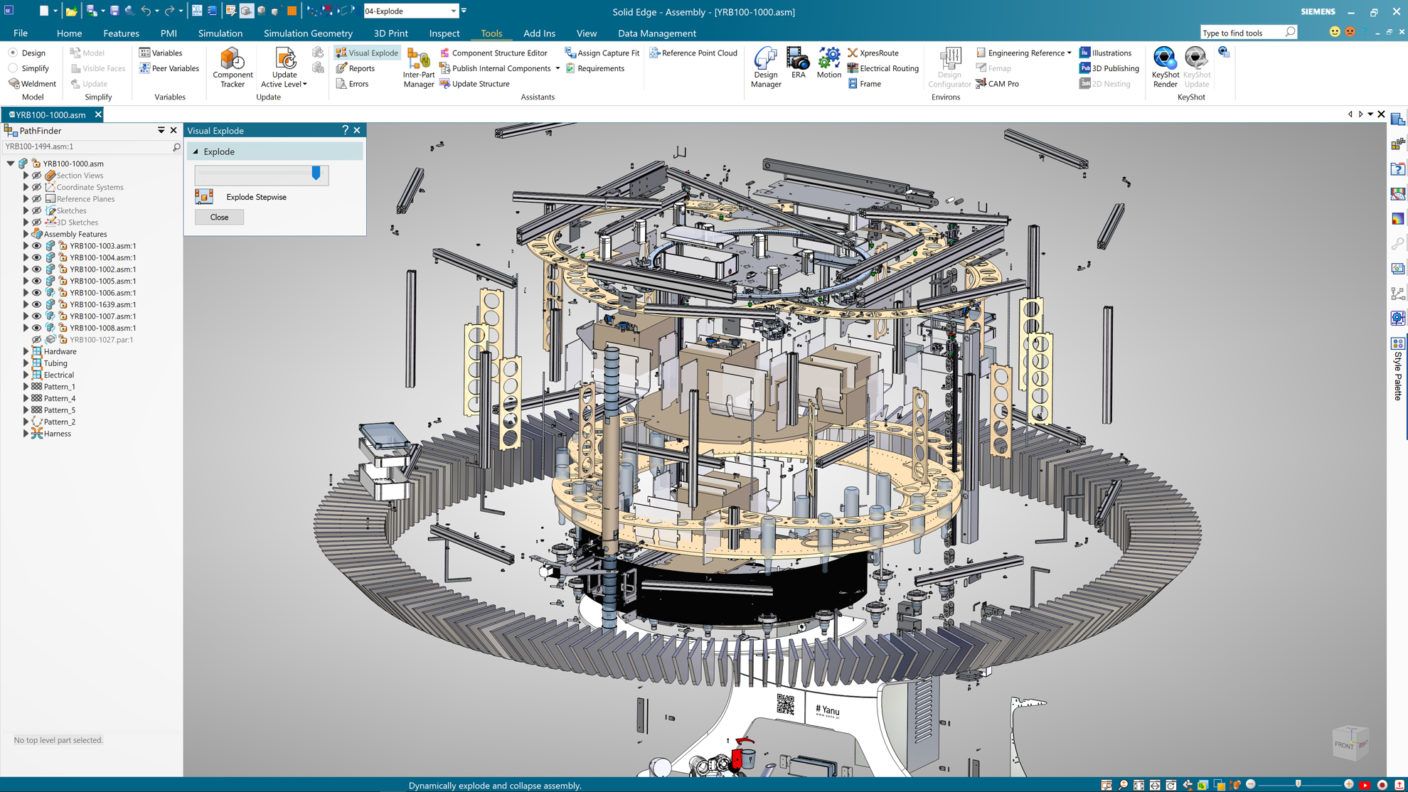

Solid Edge is the most comprehensive feature-based 2D/3D product development system on the market. It combines the speed and flexibility of direct modeling with precise measure guided feature-based modeling.

This makes working with Solid Edge easy and flexible, which is critically important in increasingly demanding modern product design.

This blog article features the most important new and improved aspects of Siemens Solid Edge.

New options in Solid Edge licensing

The new features of Solid Edge 2023 are not limited to a few details. Rather, the whole user experience has been streamlined.

Solid Edge provides comprehensive tools for 3D design, machinery CAM programming as well as preparing technical publications.

The new version isn’t solely focused on the topology mapping of 3D printing or simulation networking. The crux of development has clearly been on making your daily work better and easier.

Similarly, Xcelerator Share, the accompanying module of the SaaS subscription license, provides easier and faster collaboration.

The new, flexible licensing options are well-suited for the changing needs of small and medium-size OEMs. The new value-based licensing allows highly customizable use of software and services.

The cloud component Xcelerator Share

Xcelerator Share is a so-called cloud component that comes with the Solid Edge license, and it allows you to save your plans smoothly and safely in the cloud.

You can share your designs for review, comments and enhanced collaboration with your team or associates.

Solid Edge Xcelerator Share provides a Kanban board-style management tool for product development projects, as well as setting up meetings with project team members.

Improvements on MBD – Model Based Design

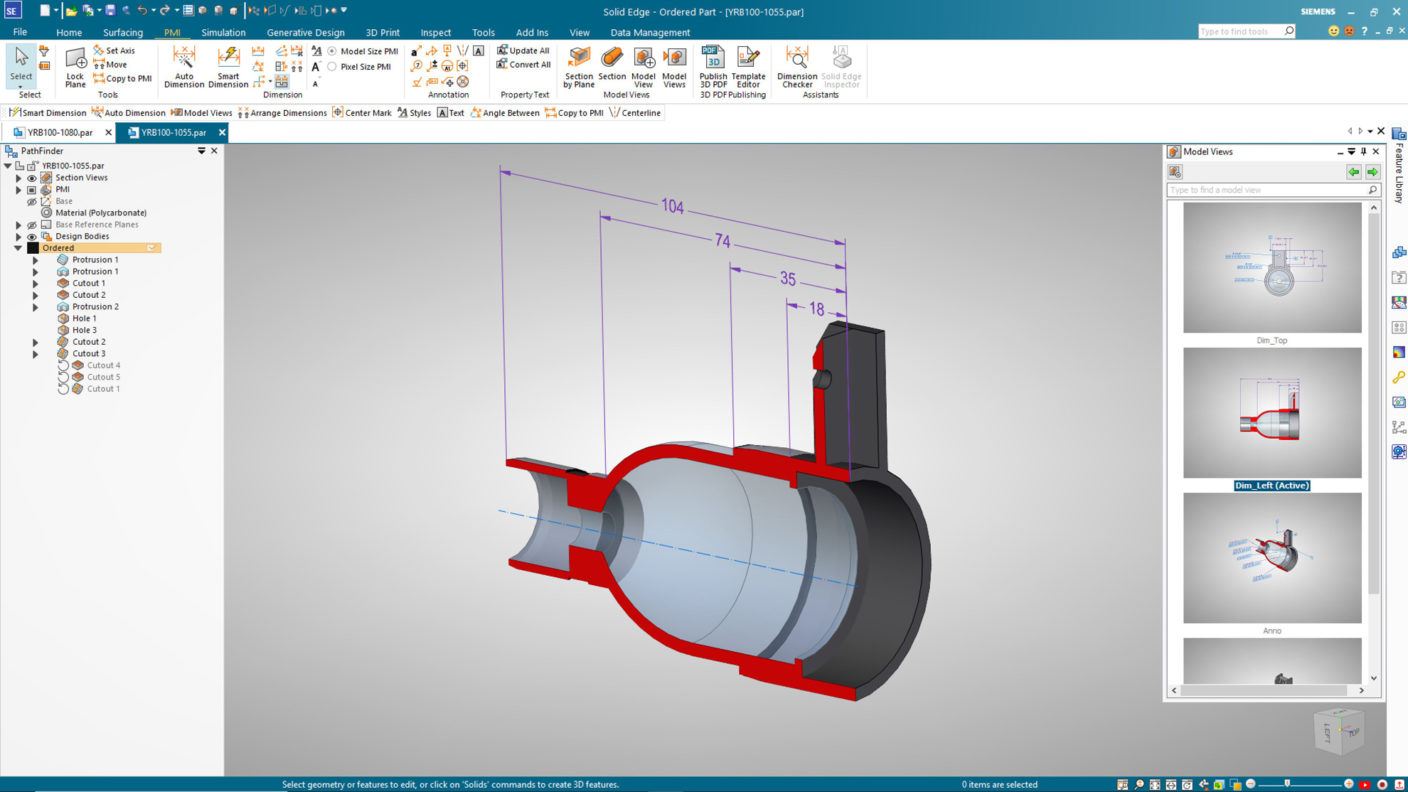

The improved MBD tools of Solid Edge 2023 allows you to drill down on the details of 3D models faster and easier than ever before. The workflow has been improved, and automation makes designing easier and faster.

The new Solid Edge Advanced PMI component provides a high-quality unified measurement creation for downstream PMI applications.

A second MBD feature is Textbox Annotation which enables you to add notes and other info to 3D PMI. The information can be displayed always aligned with the viewport, regardless of the rotation of the model.

The notes and text captions can be saved in Notes Library which makes life that much easier when the info is needed again. This feature allows you, among other things, to unify the notation syntax on the measurement process and production.

The new Auto Dimension command automatically creates PMI measurements for parts and sheet metal components. Solid Edge Advanced PMI application Dimension Checker automatically inspects the part model for under or over-constrained.

The Dimension Checker results are color coded both in the 3D model, and the interactive report and they highlight the constraint levels and identify missing tolerances.

Fit class and unit tolerances can easily be included in hole features and, thus in the designs and PMI measurements. The simultaneous hole measuring can be grouped into a single description, allowing for a more compact measuring.

New Solid Edge modules

The new Solid Edge Advanced PMI module provides high-quality measurement tools for models, to be utilized in downstream PMI applications.

Model-Based Definition has been a hot topic for quite some time and Siemens has invested heavily in the development of these tools. Measurement has been increasingly automated, for example in the deployment of measures.

An entire model, measures and imaging included, can be printed into a 3D PDF file. Engineering fit and tolerances can easily be defined in the entire feature in the design environment and be imported into designs or PMI measurements.

One of the more interesting novelties is Solid Edge Inspector which helps checking the design measurements. If the 3D model has a measure within tolerance but is missing in the design, the tool notifies you of this.

In part manufacturing, marking the inspected measurements and creation of inspection manual is automatic. If the model or the measurement is changed, Inspector saves the version history.

Solid Edge 2023 learning interface

The renewed interface has made using tools more streamlined. Work requires fewer clicks, and time is saved.

Presented already in Solid Edge 2021, the Adaptive UI is better than ever. It provides AI-like features which study how you work and intuitively predict the commands and tools you wish to employ.

Siemens software compatibility

Collaboration between software has received some interesting updates. For example, Solid Edge 2023 allows you to add kinematics to the model structure. This enhances the reusability of your designs with tools like NX and Process Simulation – and vice versa.

Even a more widely exciting novelty is the utilization of SOLIDWORKS, JT, STEP and Parasolid files directly in Solid Edge designs without a file type transformation.

Solid Edge CAM Pro additions for machining and milling

Solid Edge CAM Pro, or NX CAM, has also updated its UI, improving usability.

Siemens works increasingly with machining OEMs to provide better solutions for, among other things, design software, such as Solid Edge CAM Pro.

In CAM novelties, it’s worth mentioning Rotary Machining for 4-axis machining. It makes programming milling that much easier for rotation-symmetrical parts.

Adaptive milling, better known as dynamic milling, is now supported in 5-axis machining, adding solid chip removal to the whole process.

Wire EDM features for spark machining design have been improved. The Smart Machine Kits library in the Siemens Post Hub service allows easy access to standardized, professionally prepared post processors and machine simulation series’.

More posts

Metso aiming to improve supply chain collaboration through system simulation

Webinar (THIS WEBINAR WILL BE HELD IN FINNISH LANGUAGE) (Material will be distributed in English) August 22, 2023 – 09:00 CET Learn how Metso utilizes system simulation in their hydraulic system design. Research engineer Jesse Backman shares his learning path to system simulation, and how Metso could improve the collaboration of the supply chain through […]

Metso pyrkii kehittämään toimittajayhteistyötä systeemisimuloinnin avulla

Webinaari 22.8.2023 – 10:00 EET Tule kuulemaan kuinka Metso hyödyntää systeemisimulointia hydraulijärjestelmien suunnittelussa. Tutkimusinsinööri Jesse Backman kertoo oppipolkunsa systeemisimuloinnin pariin ja kuinka Metso voisi kehittää yhteistyötä toimittajaketjussaan systeemisimuloinin avulla. Tärkeimmät opit esitellään käytännön suunnitteluesimerkin avulla. Kuinka parantaa yhteistyötä toimitusketjussa systeemisimuloinnin avulla? Mitä systeemisimulointi on? Systeemisimulointi yhdistää yksittäisten komponenttien ominaisuudet ja vuorovaikutukset koko järjestelmän dynaamiseksi käyttäytymiseksi. […]

From Chaos to Clarity: Embracing Modularity

by Olli Uuttu • 8 min read Dear reader, have you ever wondered what goes into building a truly modular product? It’s not as easy as it may seem. While there are several proven methods available to plan and implement optimal modular architectures, it still takes effort, dedication, and discipline to succeed. I’m sure you […]